Photovoltaic (PV) industry is experiencing a rapid development under the general trend of Carbon-Neutrality-oriented development, which however has led to increasingly problems around power plant safety as the higher-power modules are being widely used. PV system designs are going up in complexity as ever newer applications and situations for use are found. How to deploy the protection design of DC side has always been the concerns and disputation in the industry. Fundamentally, misunderstanding of fuse, circuit breaker and disconnector that are generally used for protection of PV system is the root cause.

Fuse, circuit breaker and disconnector, because of their similar functions (isolation, short-circuit protection etc.), are prone to confusion and misunderstanding in the industry. However in fact, they are totally different devices, as they are significantly different in principle of protection, standard requirement, scenario of application and protective effect! As for establishment of a distribution protection system, it is necessary to fully understand the requirements on production under scenarios of application, so that devices can be reasonably deployed based on their own features to give proper application to their functions, thereby improving the work safety and reliability of the station.

- Difference in Principle of Protection

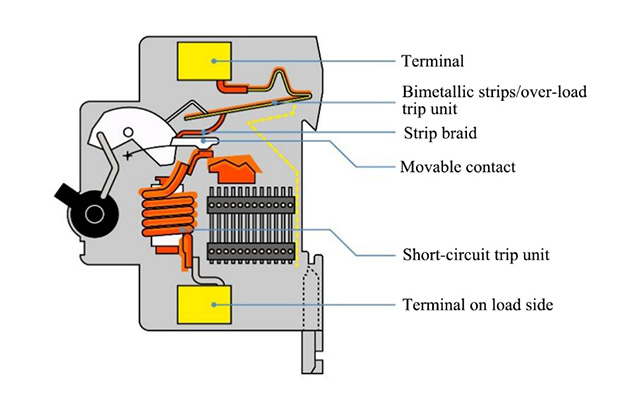

Fuse: referring to a current protector that consists of fuse element and cartridge. The fuse element will be blown out by the heat produced by itself when current outnumbers a limit for a certain time, and in this case circuit will be cut off so that the purpose of protection can be achieved.

Figure: Principle of Protection by Fuse

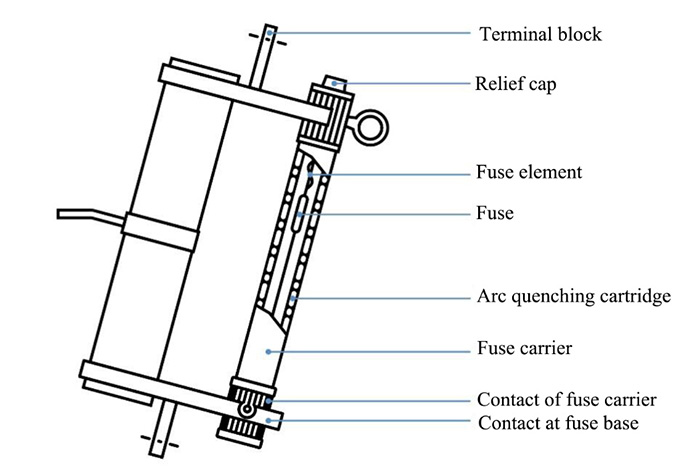

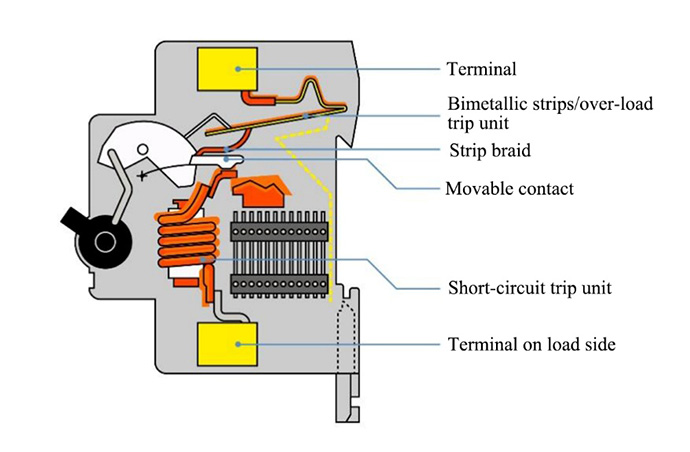

Circuit breaker: referring to a mechanical switching device that is capable of switching on/off and carrying current and consists of a contact system, an arc quenching system, an actuator and a trip unit. It is used to cut off a circuit with a failure to achieve the purpose of protection. In case of a short circuit, the counter-force spring will be overcome by a magnetic field produced by a higher current, in this case the actuator will be driven by the trip unit to switch off immediately. In an over-load case, bimetallic strips will be deformed to a certain extent at a rising temperature due to increasing current, to trigger the actuator to switch off. The higher the current is, the shorter the time for this protective action will be.

By virtue of a good arc quenching capability, circuit breaker is capable of cutting off a higher short-circuit current and can be repeatedly used, as its overall protective features are not impacted by time or environment.

Figure: Principle of Protection by Circuit Breaker

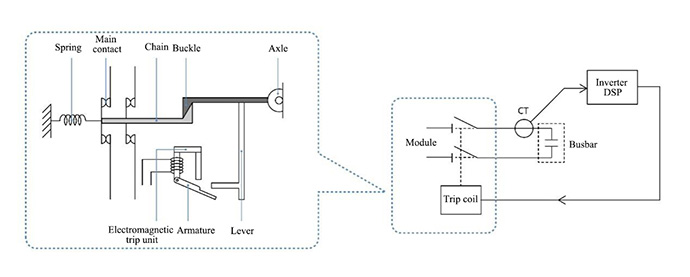

Disconnector: to serve mainly as an isolator which can form an apparent break point between electrical apparatus being overhauled and the power supply, to guarantee work safety of overhaul. In the past, manually-operated disconnector is provided on DC side of string inverter. Along with the smart development of PV station, manually-operated disconnector is replaced by motor-operated disconnector.

Motor-operated disconnector: Manually-operated disconnector is replaced by motor-operated disconnector which can act electrically in a mode of detecting current in string by use of a current transformer for inverter + DSP signals control. It is known that at 1*In, electrical life can reach to 100 -300 cycles, while at 4*In, only 5 cycles. However, the motor-operated disconnector that has replaced the manually-operated disconnector is just an upgrade in mode of acting, and therefore cannot be deemed as a protector.

With a thermal current up to 50A, the disconnector is capable of acting quickly at a current below 40A (the rated current). It should be noted that in the multi-to-one case (such as 5 strings per MPPT), backflow current may surpass 50A and may generate heat accumulated inside the disconnector, which may result in deformation and jamming in internal movable contact carrier.

Figure: Motor-operated Disconnector and Principle of Action

To sum the principles of protection and action for these three devices up: Fuse and circuit breaker are protectors which can realize a reliable mechanical protection by physical actions without request of any external circuit, while disconnector is of an isolator that relies on external circuit for detection, control etc. to reliably and electrically act, which means that in case of a power failure or failure in control circuit, performance of the disconnector may be restricted, which may bring about a risk of failure to act.

Table: Differences among the Three Devices

| Device | Circuit Breaker | Disconnector\Motor-operated Disconnector | Fuse |

| Certification criteria | IEC60947-2 | IEC60947-3 | IEC60269 |

| Features in action | Thermal and magnetic trip | Manually operated or DSP signals control | Thermal blowout |

| Arc quenching & over-load protection | Trip unit for over-load and short circuit | O | Fuse element and arc quenching cartridge |

| Over-load performance | P | O | P |

| Ultimate short-circuit breaking capacity (Icu) | Icu: dozens of times the In. | N/A | I2t (blowout) |

II. Significant Differences among Requirements on Protection from Variant Standards

GB/T 14048.2-2020 (IEC 60947-2:2019) is currently applicable to circuit breaker, while GB/T 14048.3-2017 (IEC 60947-3:2015) is currently applicable to disconnector. There are significant differences between these two standards in thermal protection, magnetic protection, multiples of rated short-circuit current for making/breaking capacity etc.

III. Specific Requirements on Protectors in Different Designs of PV System (Differences in Scenarios of Application)

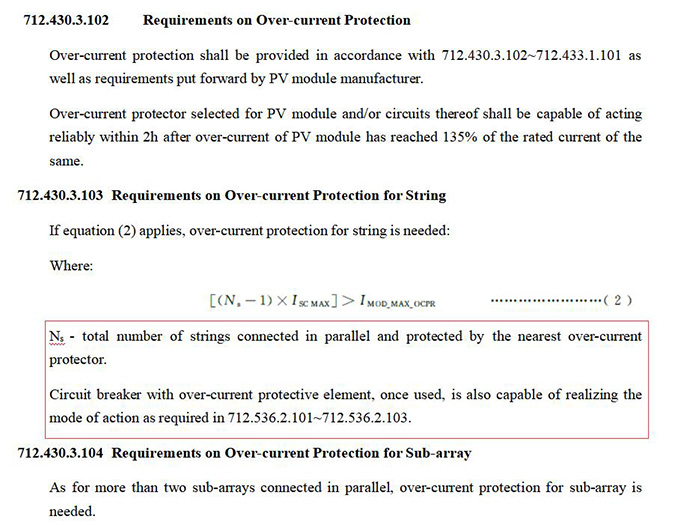

There are specific requirements on protection on DC side of PV system in GBT and IEC, specifically as follows:

1) As for a module with 3 and above strings to one path of MPPT, over-current protector is needed.

Note: Ns – number of strings connected in parallel; ISC-MOD – short-circuit current of PV module; IMOD-MAX-OCPR – maximum over-current protection ratings for PV module.

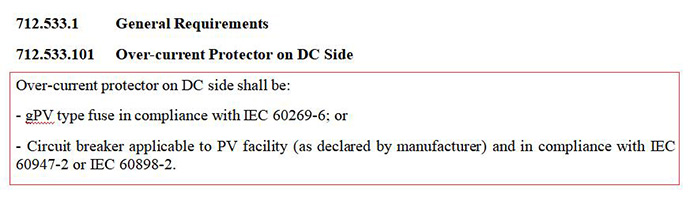

2) Over-current protector is required to be standard-compliant special fuse or circuit breaker.

Because of an inability to protection, motor-operated disconnector is totally different from circuit breaker and fuse in functions, and this is the root cause that disconnector is excluded from the range of protectors in relevant standards.

IV. Inability of Disconnector to Effectively Protect Module (Broken) in Field Test (Differences in Protective Effect)

What is the risk of providing only motor-operated disconnector (with no fuse, circuit breaker and other protectors)? Different designs for safety of inverter will lead to different consequences by over-current, specifically as follows:

1) Module with 2 strings to 1 path of MPPT: In case of a failure, the maximum short-circuit current or backflow current in the system is just equal to the short-circuit current in the module, with no impact on system safety even the disconnector fails to act.

2) Module with 3 and above strings (herein with 5 strings taken as example) to 1 path of MPPT: With 1 string gets short circuit in case of a failure, the current in the other 4 strings will flow to the point where the shorting occurs, and therefore 4 times the short-circuit current will be in the circuit in failure. Relevant parts will be damaged by uninterrupted over-current until a fire occurs if disconnector fails to act in this case.

Review on the test experiments recently concerned by industry insiders on this basis:

Reverse connection test for strings: One of the paths was taken to conduct reverse connection test (reversely between anode and cathode), i.e. a circuit was formed with this taken path of string and the other 4 paths, and in this case 70A current was formed by backflow current from such 4 paths of strings. Once a failure occurred, the disconnector failed to act, which resulted in a rapid temperature rise in relevant parts. In this case, diode of the module exploded at a temperature above 150°C.

Anti-backflow test for strings: One of the paths was taken to conduct backflow test, and in this case the backflow current (up to 30A) flowed from the other 4 paths of strings to the string in failure. Once a failure occurred, the disconnector failed to act, which resulted in a rapid temperature rise in relevant modules and circuits (to 76.8°C, by 49°C in one minute).

Summary: Motor-operated disconnector is not equivalent to a circuit breaker.

Motor-operated disconnector is different from circuit breaker in principle of protection (action) and standard requirements, and therefore these two are not mutually replaceable. Disconnector can be used as a redundancy configuration jointly with such protector as circuit breaker to improve the protective capacity of the system, but should never be provided independently as a substitute to fuse or circuit breaker.

Care must be taken to select and configure safety protectors.